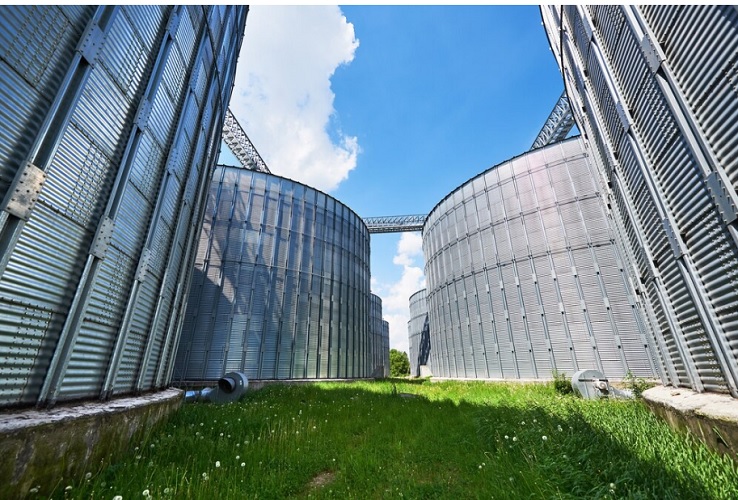

–The number of US biogas plants processing food waste has grown by 19% over five years, now totaling over 300 facilities.

–These facilities collectively process approximately 12.8 million tonnes of food waste annually across standalone, wastewater, and farm systems.

–Operational RNG facilities in North America have the potential to supply 2.25 million tonnes of biogenic CO2 per year.

–Currently, less than 5% of facilities utilize on-site CO2 capture systems, indicating a significant market gap.

This infrastructure expansion arrives as the US industrial sector scrambles to secure reliable sources of carbon dioxide. With traditional CO2 sources struggling to meet rising demand, the biogas sector is emerging as a pivotal player in stabilizing the supply chain. By utilizing anaerobic digestion, these facilities convert organic streams—ranging from manufacturing scraps to wastewater solids—into renewable energy and biogenic CO2.

Industry Perspectives Data: from the American Biogas Council (ABC) indicates that 118 of these facilities exclusively recycle food waste, managing over 10 million tonnes of inedible scraps annually. An additional 124 wastewater plants and 62 farms integrate food waste into their digestion processes.

Patrick Sergass, Executive Director of the American Biogas Council, emphasized the underutilized economic potential of organic waste streams.

“The US still overlooks the enormous value in food processing scraps and inedible food,” Sergass stated. “We hope more municipalities and industrial food processors will choose to invest in biogas systems to recycle their resources locally.”

The implications extend beyond power generation. Speaking at gasworld’s North American CO2 Summit, Erica Chase, President of CleanCycle Carbon, identified Renewable Natural Gas (RNG) production as a critical, under-tapped source of CO2.

Bioenergy Business Analysis: The divergence between potential supply and current infrastructure presents a massive capital expenditure opportunity for technology providers. While the RNG Coalition identifies 474 operational facilities with the potential to supply 2.25 million tonnes of CO2 annually, the fact that less than 5% currently have capture systems in place signals a major efficiency gap. For investors and plant managers, retrofitting existing anaerobic digesters with CO2 liquefaction technology represents the next logical step in revenue diversification, transforming a waste byproduct into a tradable industrial commodity.